The Design and Development of an Extravehicular, Stratospheric Exploration (StratEx) Pressure Suit

IN December of 2011 a StratEx team consisting of ILC Dover, Paragon SDC, and United Parachute Technologies was formed with the goal of designing and developing a pressure suit, launch, flight and recovery system that would enable a person to directly and safely interact with high altitude, stratospheric environmental conditions for an extended period of time. A small, lightweight, highly mobile single user system that operated in the same context as a SCUBA system for underwater survival and exploration was envisioned. Like a SCUBA system, one basic premise of this type of stratospheric exploration system was that minimal training would be required for its successful and safe operation thus opening access to the stratosphere for both leisure and scientific endeavors to those without an expert level of skydiving and ballooning experience. Such a system could then be applied toward more mission centric goals, such as applied science and exploration, than just merely successful occupant survival and recovery

A. History of Stratospheric Balloon Flights

The very first efforts to venture into the stratosphere using balloons began in the 1930s with altitudes of over 70,000 ft being attained; however they were limited by the heavy rubber materials used in the construction of the balloons at that time. While lighter materials were being investigated, the breakout of the Second World War interrupted high altitude ballooning for several decades. After the war, the introduction of these lighter materials, together with interest demonstrated by the United States military, reinvigorated research into manned access to the stratosphere. The following are the major United States historical military and civilian programs that have sought to provide this type of access.

1. Strato-Lab I-V

High altitude exploration began in earnest in the 1950s and early 1960s with the Navy’s Strato-Lab project which was initiated to look at biomedical requirements for America’s manned rocket program and a myriad of other scientific objectives including gathering data in the fields of astronomy, atmospheric physics, and human physiology. Five numbered flights were undertaken and included both open and pressurized gondolas. Progressively they included flights that ranged from 76,000 to 113,740 ft in altitude. The longest of these flights, Strato-Lab III, reached 82,000 ft and remained aloft for nearly 35 hours in a pressurized gondola. Strato-Lab V, the last and highest flight in the series used an open gondola together with the B.F. Goodrich Mark IV full pressure suit, the precursor to the Project Mercury suits. This would mark the first use of a full pressure suit for exposed stratospheric ballooning

For all of these flights the aeronauts stayed with their respective capsule or gondola for the entire duration of the flight. A common theme amongst these flights was difficulty controlling the descent rate of the balloon. On more than one occasion unintentionally fast and potentially fatal descent rates had to be overcome by discarding all ballast as well as all other equipment that could be expended. The program’s only fatality came after the successful completion of the Strato-Lab V flight when one of the pilots slipped into the ocean after a water landing and drowned when his suit filled with water and rescue personnel could not retrieve him in time.

2. Manhigh I-II

As the Navy was progressing with their Strato-Lab program the Air Force was concurrently conducting a similar manned high altitude program of their own. Dubbed Project Manhigh, it began in 1955 with the objective of studying the effect of cosmic rays on human anatomy. For this project three flights were conducted using pressurized capsules each containing a single occupant. These three capsules achieved altitudes that ranged from just under 97,000 ft to just over 101,500 ft with Manhigh II setting the original endurance record of 32 hours before it was broken the following year by the Navy with their Strato-Lab III flight. As with the Strato-Lab flights, personal ‘bail-out’ parachutes were available for extreme emergencies, however the nominal concept of operations dictated that capsule pilots remain in the capsule from launch through to touchdown.

Both Manhigh II and III experienced difficulty with descent rate control which was made worse in the case of Manhigh III where the pilot also experienced a loss of cooling. This placed the core body temperature of the pilot in the range of 107˚ F for an extended period of time. If not for the unusual ability of the pilot to endure the elevated temperature, many associated with the program believe that conditions within the capsule would not have been survivable.

3. Excelsior I-III

With the dawn of manned rocket flight in the 60s, and the increased ability of military pilots to fly higher and faster, there were increasing concerns regarding the ability of an astronaut or pilot to survive a high altitude ejection or bailout from an aircraft or spacecraft. Open questions about how a pilot should freefall after ejection, what altitude a parachute should be opened, and how a pilot would survive environmental conditions remained unanswered. And unfortunately low altitude testing could not provide either the right environmental conditions or freefall speeds necessary to provide these answers. Thus in 1959 Project Excelsior was authorized to perform a series of full-scale stratospheric skydives.

Despite careful planning and preparation, the flight of Excelsior I was a near tragedy. This initial flight was only slated for 60,000 ft, however helmet fogging and the glare from the unfiltered sunlight made it difficult for the pilot to read his instruments and arrest his balloon ascent. Additional problems in removing himself from his seated position prevented him from actually jumping until he was at almost 76,000 ft. During the descent the main parachute deployed early and in the thin air wrapped around the pilot’s body before it could properly fill. The pilot also entered an uncontrolled flat spin which caused him to lose consciousness until after he had landed. Only a well-designed set of safety features built into the reserve parachute system saved his life.

Despite the near fatal outcome of Excelsior I project managers were able to secure the go-ahead for a second jump attempt. The difficulties encountered in the first jump, caused mostly by the unexpected effects of the extreme cold on the equipment, were taken care of in short order and less than one month later an Excelsior II flight was completed with a successful jump from 74,700 ft. The rousing success of Excelsior II paved the way for the ultimate goal of the Excelsior program, a jump from over 100,000 ft.

Almost one year later, Joe Kittinger, also the pilot for the first two Excelsior flights, made the historic journey to 102,800 ft where he would successfully survive a four minute and thirty seven second freefall of nearly 85,000 ft. The only major equipment malfunction of the Excelsior III flight was the failure of the right glove of Kittinger’s partial pressure suit to pressurize properly. Post flight examination and testing of the suit concluded that the suit and pressurization system would have to be rethought and probably overhauled before any further altitude jumping could be conducted. Because the program had demonstrated such great success in its Excelsior III mission however, the decision was made to cancel the program rather than procure the budget required to upgrade the suit.

4. Strato-Jump II-II

Later in the 1960s amateur parachutist Nicholas Piantanida became obsessed with the idea of breaking both the official world record for the highest parachute jump set at 83,523 ft by the Soviet Air Force pilot Yevgeni Andreyev in 1962 and the unofficial record set by Joe Kittinger in the Excelsior Program several years earlier. He personally sought money from commercial sponsors, aid for training from the United States Air Force, and a pressure suit which he received on loan from the David Clark Company to enable his own ‘Strato-Jump’ program. Strato-Jump I ended at only 16,000 ft with a balloon failure, however Strato-Jump II soared to more than 123,500 ft becoming the highest manned balloon flight in history at that time. Unfortunately he was unable to disconnect his oxygen line and was forced to return to Earth under parachute inside the gondola. A third attempt was made several months later however, Piantanida’s helmet depressurized at 57,000 ft which left him brain damaged and in a coma from which he would never recover.

5. Red Bull Stratos I-II

With the move of world governments into the space age and away from manned, high altitude ballooning both Kittinger’s and Piantanida’s unofficial records stood from when they were set in the 60s until they were once again challenged in 2012. Red Bull GmbH, a sports drink company famous for advertising its product with the use of sponsored athletes who perform extreme stunts, funded the Red Bull Stratos program in an effort to publicly best these fifty year old records. With a goal of minimizing risk, program engineers chose to use a pressurized capsule that would only be depressurized just prior to the jump attempt at altitude. Use of a pressurized capsule would limit direct exposure of the suited pilot to the harsh stratospheric environment to only just the few minutes required for descent, and provide the required consumables for the two and a half hour ascent. Renowned Austrian skydiver and BASE jumper Felix Baumgartner was chosen to pilot the Stratos missions and successfully completed two test jumps of 71,581 ft and 96,640 ft respectively before breaking both the manned balloon and skydiving records later that same year. The skydive records attained for that final mission were the highest skydive altitude (127,852 ft), maximum vertical speed without a drogue (843 mph), and vertical distance of freefall (119,431 ft). Baumgartner also became the first person to break the sound barrier without any type of mechanical assist.

To note, Baumgartner had the ability to deploy a stabilizing drogue parachute at any time but opted not to use it in the pursuit of a faster freefall record. This lack of a deployed drogue parachute increased the risk of entering a flat spin due to small center of gravity perturbations at high air speeds, which is what ultimately happened to Baumgartner during his freefall. Were it not for his extensive skydiving experience this flat spin may not have been recoverable, although an increase in spin rate to dangerous levels would have automatically deployed the drogue stabilization parachute. Additionally, active heaters in the suit helmet visor were unable to prevent helmet fogging for portions of the mission. Several modified S1034 full pressure suits, similar to those worn by high altitude Air Force pilots, were used for the Red Bull Stratos program

B. StratEx Program Overview

In the midst of the very public preparations of the Red Bull Stratos team Dr. Alan Eustace, Senior Vice President of Knowledge for Google, amateur skydiver, and aerospace enthusiast, noted that one common element to all of the high altitude programs to date was the use of either a pressurized capsule or an unpressurized gondola to house the pilot and related equipment for at least the ascent portion of the mission. In an era where people are regularly and safely conducting six and seven hour long spacewalks using spacesuits with attached life support systems he surmised that it would be possible to fabricate a complete flight and recovery system that utilized a self-contained suit/life support system capable of continuous, direct and safe exposure to the environment without the use of a capsule or gondola. Doing so, he saw, would provide several distinct advantages:

1) A Significant Reduction in Payload Mass

At altitudes above 100,000 ft atmospheric pressure is already near zero and it changes by smaller and smaller amounts as altitude increases. In other words as the desired flight altitude increases more significant increases in the buoyancy of a balloon system are required. The Red Bull Stratos balloon, for example, was nearly ten times the volume of the balloon used by Joe Kittinger for the Excelsior III jump. Increasing buoyancy means either increasing the size of the balloon, as was done by the Red Bull Stratos team, or somehow reducing the total system mass. And at nearly 30 million cubic feet in capacity (more than 400 ft in diameter) the ability to manufacture the largest modern lifting balloons is already nearing its limit. Reducing the effective ‘capsule’ mass to just the mass of a small, body mounted life support system stood to save thousands of pounds when compared to prior programs. This kind of mass savings translates into increased altitude thus maximizing access to a fuller range of Earth’s stratosphere

2) No Requirement for Disconnect Operation

By using a self-contained, continuously attached life support system the pilot is then free from having to disconnect from capsule mounted pilot operated systems in order to descend, a lesson learned from the loss of the Strato-Jump II mission.

3) Simplified Balloon ‘Exit’

With a self-contained, hanging suit system a nominal balloon ‘exit’ does not require an actual exit at all. Simply releasing the suited pilot, versus requiring an equipment laden pilot to stand and maneuver, would be all that was required. A hanging pilot also has the advantage of being able to assume a stable position prior to release, thus reducing the chance of rotational inputs upon vehicle separation. With increased altitude also comes an increase in both freefall time and speed prior to attaining a thick enough atmosphere to inflate a stabilization parachute. Maintaining an initial stable attitude in this region is desirable because there is no way to arrest unwanted rotation in the extremely thin air.

4) Immediate Abort Capability

With safety being the paramount concern, Dr. Eustace also noted that a hanging pilot could be released immediately upon detection of any flight system anomaly at any time. Without having to depressurize a capsule, disconnect any lines or hoses, or even to just stand and maneuver to the edge of a gondola, it would be possible to immediately separate the pilot from the balloon and enact recovery protocols. As with a nominal release, no action on the part of the pilot would be required for emergency recovery operations to proceed.

With these thoughts in mind Dr. Eustace assembled the StratEx team to design, develop, manufacture, and test such a system. As flown the final flight system weighed in at just under 600 lbs, including the bodyweight of the pilot, and was comprised of the pressure suit assembly (PSA), the life support Equipment Module (EM), the parachute/drogue recovery system, the balloon, and the Balloon Equipment Module (BEM) including the pilot attachment rigging. Additionally, ground support equipment was required to enable pilot suit-up, launch, and recovery operations. Dr. Eustace acted as the pilot for all manned flight testing

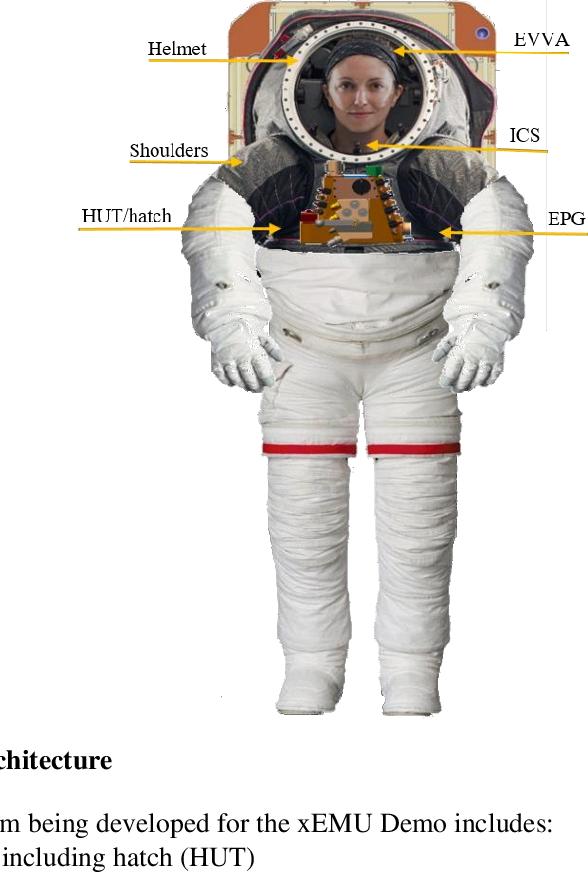

1. Pressure Suit Assembly (PSA)

The full Pressure Suit Assembly (PSA) used by the StratEx team was designed and developed for the specific purpose of long duration exposure to high altitude and interim environments.

2. Equipment Module (EM)

The EM is a front mounted life support pack. This pack has three main responsibilities which include providing temperature controlled thermal fluid to the pilot, providing temperature and pressure regulated oxygen to the suit and housing all flight avionics. The equipment module also serves as a mounting location for several of the pilot interfaces like parachute pull handles. The fluid system consists of a fluid heater and controller to bring heated fluid to the pilot’s Liquid Thermal Garment (LTG) in flight, ports to provide cooled fluid to the LTG on the ground, and a heat exchanger / conductive contact system to heat both the oxygen stream and the flight computer box using the heated fluid loop. The oxygen system provides regulated oxygen at ~90 psi to the suit where the demand regulators are mounted. The oxygen stream is heated via a heat exchanger that exposes the oxygen to the heat from the heated fluid. Finally the avionics system, with the capability to both transmit and receive, monitors many aspects of the life support system and interacts with mission control and ground vehicles. Independent voice radios in the equipment module transmit pilot voice signals, and a pilot display panel shows the pilot key life support values.

The equipment module integrates to the suit via two structural mounting brackets that connect to the helmet and body seal closures of the suit. The EM passes fluid, oxygen and electrical signals in and out of the suit via the main suit pass-through.

3. Parachute/Drogue Recovery System

The parachute system used in the StratEx program was a modified United Parachute Technologies Sigma tandem parachuting rig. The jump performed was not a tandem parachute jump but the Sigma Tandem rig was well suited for the weight of the system, and its general architecture (which used a stabilizing drogue parachute) fit the StratEx system requirements with little alteration. The final parachute system resembled a standard Sigma rig but with a few key differences. First the main and reserve parachute containers were switched so that the main container was above the reserve (which is opposite of a standard container); second, the connection point of the drogue parachute was higher on the pack than normal; and finally, the drogue itself was physically larger than a standard tandem skydiving system.

The integration of the parachute pack to the relatively complex suit system also drove substantial alterations to the attachment rigging. The parachute pull handles were moved from the main lift webs to the EM where the suited pilot could easily reach them.

The parachute pack was held to the system via fixed-length leg loops around the upper thighs of the suit and main lift webs going over the suit shoulders. High-strength clips held the chest straps to the EM central frame.

And while a discussion of the development and testing of the drogue system is beyond the scope of this paper it is worth noting that months of very extensive high altitude testing with a mass and volume equivalent pilot simulator did occur with the intent of preventing pilot spin during any portion of the freefall descent. For actual flight the drogue parachute was released at the same moment the pilot was released from the balloon, and no significant amount of spin was noted during freefall.

4. Balloon/Balloon Equipment Module (BEM)

Three different sized polyethylene balloons were used to complete the manned portion of the high-altitude flight test campaign. For the three altitudes achieved (56,800 ft, 105,771 ft, and 135,890 ft) the maximum volume of each of these balloons was 3,000 m3 , 48,000 m3 , and 328,000 m3 respectively. Each balloon was crowned with a valve that opened to initiate descent and equipped with a destruct fuse that would be commanded to ignite and produce a large hole in the balloon once the pilot was dropped clear. Balloon avionics were mounted to the BEM which hung just beneath the balloon. The BEM also served as the mounting point for the balloon ballast, cameras for monitoring flight operations, and a recovery parachute for the avionics box which was ejected prior to commanding the balloon destruct sequence. The pilot attachment and release rigging hung just below the BEM. Although not the primary topic of this paper it is worth noting that successful pilot release was considered critical to pilot survival and was the only system with tertiary redundancy; pyrotechnic cutters that could be commanded from the BEM avionics, pyrotechnic cutters that could be commanded from the suit EM avionics, and a manual pull release that could be performed by the pilot.

5. Ground Support Personnel/Equipment

To enable suit donning, balloon launch, mission monitoring and commanding, and post-flight recovery operations a host of ground support equipment and personnel was required. Pre-launch operations included a four hour, pure oxygen pre-breathe as a conservative means of mitigating the risk of decompression sickness at altitude and required a mobile ground cart to provide power, oxygen, and cooling without using flight consumables for preflight operations. A large forklift was used to move the suited pilot and mobile ground cart to the launch site where the pilot was then set on a small, wheeled ‘launch sedan’ that allowed him to be positioned appropriately beneath the balloon and attached securely. This wheeled sedan also served as a launch platform to prevent the pilot from being dragged in the event that side loads on the balloon caused some horizontal loading on the suit prior to lifting the pilot clear after balloon was released. Another vehicle with a custom built front end attachment was also used to gently raise the balloon as it was filled with helium and lifted to its standing height from its rolled out length. The balloon was anchored to a large steel plate until it was released. In-flight operations were monitored and commanded by a mission control center with consoles for directing the flight; monitoring the weather; monitoring the health of the balloon, suit, and pilot; and directing recovery operations.

Two trucks, two helicopters, and a fixed wing aircraft were used for post-flight pilot and balloon recovery operations. These vehicles operated under the direction of mission control recovery personnel. For the sake of redundancy one of the recovery trucks and one of the recovery helicopters were set up with small, mobile versions of the mission control infrastructure and were capable of independent communication with and commanding of both the balloon and pilot EM avionics.